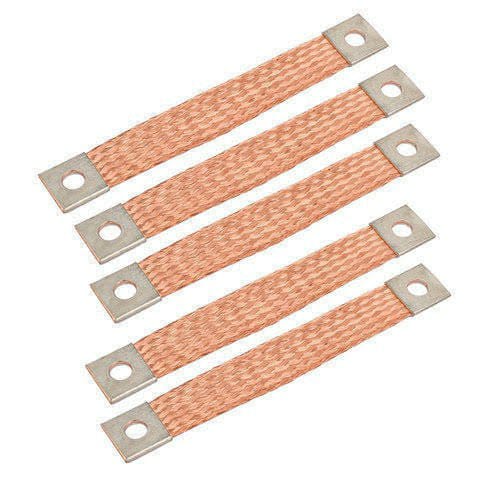

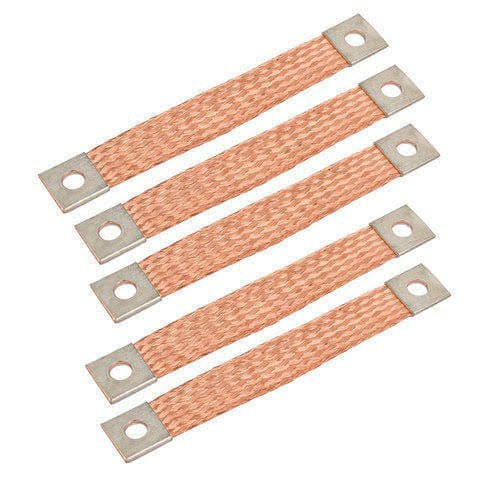

COPPER BRAIDED FLEXIBLE

1000.0 INR/Piece

Product Details:

- Surface Treatment Polished

- Product Type Other

- Shape Rectangular

- Color Copper

- Warranty 1 Year

- Click to View more

X

COPPER BRAIDED FLEXIBLE Price And Quantity

- 1 Piece

- 1000.0 INR/Piece

COPPER BRAIDED FLEXIBLE Product Specifications

- Copper

- Other

- Polished

- Rectangular

- 1 Year

COPPER BRAIDED FLEXIBLE Trade Information

- Cash on Delivery (COD) Cash Advance (CA) Cheque Cash in Advance (CID) Letter of Credit (L/C)

- 1000 Piece Per Week

- 7 Days

- No

- Asia Australia South America Eastern Europe Middle East Africa Central America North America Western Europe

- All India

Product Description

Specification

Braided Copper Flexibles are high-quality, flexible conductors made from finely stranded copper wires woven into a braided pattern. This design ensures maximum flexibility, making them suitable for applications requiring repeated movement, vibration resistance, and secure, stable conductivity. These conductors are frequently used for grounding, bonding, and power connections in various industries, such as electrical engineering, telecommunications, renewable energy, and automotive systems.

The braided structure allows for better current distribution, minimizes the risk of overheating, and provides resilience to mechanical stress. Braided copper flexibles are available in a range of sizes and configurations to meet diverse specifications and electrical load requirements.

Key Features

- High Flexibility: The braided construction provides excellent flexibility and ease of handling.

- Superior Conductivity: Made from pure copper for maximum electrical conductivity and minimal power loss.

- Vibration Resistance: Ideal for applications with vibration or mechanical movement, reducing wear and tear.

- Heat Dissipation: The braid structure enables efficient heat dissipation, preventing overheating.

- Corrosion Resistant: Available with options like tin or nickel plating for corrosion protection in harsh environments.

- Customization Available: Custom sizes, lengths, and terminations to meet specific project needs.

Frequently Asked Questions (FAQs)

1. What are braided copper flexibles typically used for?

Braided copper flexibles are widely used for grounding, bonding, and as electrical conductors in applications requiring flexibility and durability. Common industries include power generation, automotive, telecommunications, and renewable energy.

2. Why choose braided copper flexibles over solid copper conductors?

The braided design provides greater flexibility, making it suitable for dynamic applications involving movement or vibration. Additionally, they dissipate heat effectively, reducing the risk of overheating.

3. Are braided copper flexibles available in different sizes and configurations?

Yes, they come in various widths, lengths, cross-sectional areas, and termination types to suit specific requirements. Customizations are available to meet unique needs.

4. Can these flexibles withstand harsh environmental conditions?

Yes, braided copper flexibles can be coated with materials like tin or nickel to improve corrosion resistance, making them suitable for use in demanding environments.

5. How do I know what size or configuration I need for my project?

The appropriate size and configuration depend on the current load requirements, length, and environmental factors of your application. Consulting an expert or referring to industry standards can help you select the best fit.

6. Are these braids easy to install?

Yes, braided copper flexibles are designed for easy installation, especially in compact spaces or where the conductor needs to bend around obstacles.

7. Can I customize braided copper flexibles for specific applications?

Absolutely! Many suppliers offer customized lengths, widths, cross-sectional areas, and termination styles to meet specific project needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free