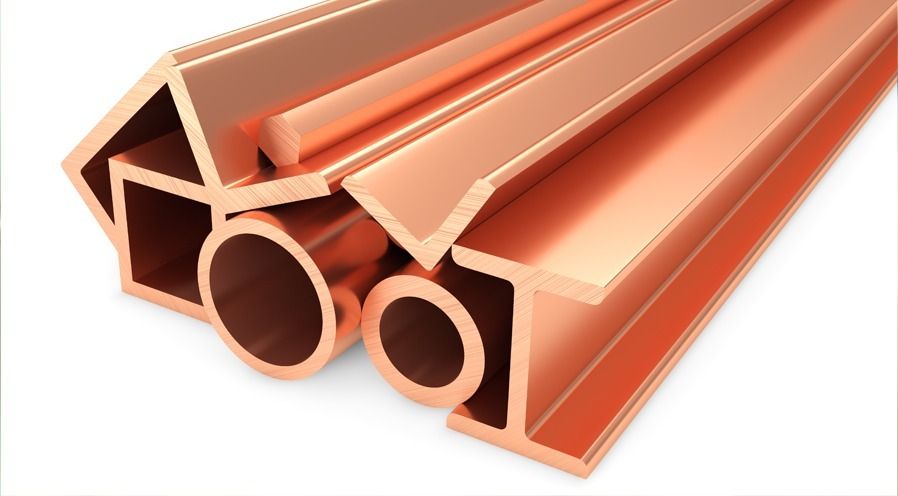

COPPER PROFILE AND SECTIONS

Product Details:

- Surface Treatment Mill Finish

- Product Type Copper Section

- Shape Other

- Alloy Yes

- Color ORANGE - RED - BROWN

- Warranty NA

- Click to View more

COPPER PROFILE AND SECTIONS Price And Quantity

- 100 KGS Kilograms

- 900 INR/Kilograms

COPPER PROFILE AND SECTIONS Product Specifications

- Other

- Yes

- Copper Section

- ORANGE - RED - BROWN

- NA

- Mill Finish

COPPER PROFILE AND SECTIONS Trade Information

- 5000 Kilograms Per Week

- 30 Days

- Yes

- Contact us for information regarding our sample policy

- 1. Standard Packaging for Copper Profiles and Sections Wooden Pallets, Strapping, Plastic Wrap or Shrink Wrap, Wooden Crates, Cardboard Boxes.

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- 1. ISO Certifications 2. EN (European Norm) Standards 3. ASTM (American Society for Testing and Materials) Standards 4. Bureau of Indian Standards (BIS)

Product Description

Copper profiles and sections refer to copper materials that are processed into specific shapes or crosssectional forms commonly used in a wide range of industrial electrical and construction applications These profiles and sections are produced in a variety of dimensions and shapes offering versatile solutions for different uses Below is a detailed description of copper profiles and sections

Types of Copper Profiles and Sections

- Copper Bars Available in various crosssections such as rectangular square or hexagonal Copper bars are widely used in electrical applications like busbars and conductors due to coppers excellent electrical conductivity They are also used in manufacturing plumbing and various architectural applications

- Copper Rods Typically used for wire drawing copper rods are drawn into thin wires or used in the manufacturing of components that require a high degree of electrical conductivity

- Copper Tubes Copper tubes are available in round square or rectangular shapes and are commonly used in plumbing HVAC systems refrigeration and heat exchangers due to their resistance to corrosion and heat conductivity

- Copper Plates These are flat thick sheets of copper used in a variety of applications including electrical components as base materials for printed circuit boards in decorative applications or for custom fabrication

- Copper Angles Copper angles are Lshaped sections used in structural and framing applications They offer both strength and durability while maintaining the corrosionresistant properties of copper

- Copper Channels These sections are Cshaped or Ushaped and are used in construction electrical and industrial applications often to house wires or cables or as part of a larger framework in building structures

- Copper Flats These are thin flat sections of copper typically used in electrical industrial and decorative applications They are often used for making copper strips as well as for architectural finishes

Manufacturing Process

- Copper profiles and sections are made through a variety of processes such as extrusion rolling and drawing The specific process depends on the desired final shape and size

- Extrusion This process forces copper material through a mold or die to form specific crosssectional shapes Its commonly used for producing complex shapes like channels angles and tubes

- Rolling Copper is passed through a series of rollers to reduce its thickness or to create flat sheets or strips Its a highly efficient process for creating copper plates or sheets

- Drawing Copper rods or wires are drawn through a die to reduce their diameter which is especially useful in wire manufacturing for electrical applications

Applications

Copper profiles and sections are used in a wide variety of industries and applications

- Electrical and Electronics Due to its high electrical conductivity copper profiles and sections are extensively used in the manufacturing of electrical conductors wiring and connectors Copper busbars copper rods and copper strips are particularly common in electrical distribution systems

- Plumbing and HVAC Copper tubes are widely used in plumbing for water supply lines heating systems and air conditioning units due to coppers resistance to corrosion bacteria growth and high thermal conductivity

- Construction and Architecture Coppers aesthetic appeal durability and resistance to weathering make it a popular material for architectural profiles such as copper gutters downspouts and flashing Copper is also used in decorative elements and facades

- Industrial Applications Copper sections like rods angles and channels are used in various industrial applications such as machinery fabrication structural support and heat exchangers

Benefits of Copper Profiles and Sections

- Corrosion Resistance Copper naturally develops a protective patina layer over time making it highly resistant to corrosion and degradation especially in harsh environments

- Electrical Conductivity Copper is one of the best materials for electrical conductivity making it the preferred choice for wiring busbars and electrical systems

- Malleability and Formability Copper can be easily shaped and formed into various profiles and sections making it ideal for custom applications in diverse industries

- Durability Copper profiles are longlasting and can withstand extreme conditions offering a long service life with minimal maintenance

- Aesthetic Appeal Copper has a distinctive warm color that naturally develops a greenish patina over time which is desirable for architectural and decorative applications

Grades of Copper

- Copper profiles and sections come in various grades each designed for specific purposes

- Commercial Grade Copper C11000 Known for its high conductivity and malleability commonly used in electrical conductors and generalpurpose applications

- Oxygen Free Copper C10200 Used for more demanding electrical applications where maximum conductivity is required such as in highend audio equipment or telecommunications

- Brass and Bronze Alloys These are copper alloys copper with zinc or tin used when higher strength or resistance to wear and tear is required

Custom Solutions

Copper profiles and sections are available in standard shapes but they can also be customized for specific applications Companies offering copper products can often create custom profiles or sections based on unique specifications for size thickness or form making copper a versatile solution for a wide range of industrial and commercial needs

Conclusion

Copper profiles and sections offer a combination of electrical mechanical and aesthetic benefits that make them invaluable across a variety of industries Whether in electrical wiring plumbing systems or architectural designs coppers inherent properties such as high conductivity corrosion resistance and malleability ensure that it continues to be a preferred material for many high performance applications

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS