COPPER PIPE AND BRASS PIPE

COPPER PIPE AND BRASS PIPE Specification

- Condition

- New

- Diameter

- 6 mm to 101 mm

- Outer Diameter

- 6 mm to 101 mm

- Surface Treatment

- Polished, Annealed, or Electrolytic

- Size

- Available from 1/8 inch to 4 inch

- Finish

- Seamless or Welded

- Product Type

- Round pipe or tube

- Shape

- Round

- Strength

- High tensile strength for both copper and brass pipes

- Hardness

- Semi-hard, soft, hard

- Alloy

- Copper: Pure copper or C12200; Brass: CW614N, CuZn39Pb3

- Grade

- Copper: TP2, C11000; Brass: CZ108, C26000

- Length

- Custom lengths available from 1 meter up to 6 meters

- Width

- Not applicable for pipes

- Thickness

- Ranges from 0.5 mm to 5 mm

- Color

- Copper pipe: reddish brown; Brass pipe: yellowish gold

- Density

- Copper: 8.96 g/cm³; Brass: 8.44 g/cm³

- Applications

- Plumbing, HVAC, refrigeration, gas lines, decorative use

- Weight

- Depends on length, diameter, and wall thickness

- Packing

- Plastic wrap, wooden box, or standard bundle

- Manufacturing Process

- Drawn, extruded, or pressed

- Corrosion Resistance

- Superior in most atmospheric and water environments

- Pressure Rating

- Up to 600 psi (varies by size)

- Melting Point

- Copper: 1083°C; Brass: 900-940°C

- Pipe Base Material

- High purity copper or premium brass alloy

- Conductivity

- Excellent electrical and thermal conductivity

- Workability

- Easy to bend and join using welding, soldering, or brazing

- Inner Diameter

- Ranges from 4 mm to 95 mm

- Delivery

- Within 7-30 days after order confirmation

- Lead Content

- Low-lead or lead-free options available

COPPER PIPE AND BRASS PIPE Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Days after Acceptance (DA), Letter of Credit at Sight (Sight L/C), Letter of Credit (L/C), Cheque

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 15 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- WOODEN BOX , HESSIAN CLOTH AND PALLETE PACKING

- Main Export Market(s)

- Asia, Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America

- Main Domestic Market

- All India

- Certifications

- ISO, ASTM, EN AND MANY MORE

About COPPER PIPE AND BRASS PIPE

Copper pipes are versatile tubes made from high-purity copper, known for their exceptional durability, corrosion resistance, and thermal and electrical conductivity. Copper piping is widely used in various sectors, including:

- Plumbing: For potable water systems due to its ability to resist corrosion and provide a safe, non-reactive surface for water. It is also resistant to bacterial growth and helps maintain water quality.

- HVAC: In heating, ventilation, and air conditioning systems, copper pipes carry refrigerants and withstand high and low temperatures effectively.

- Gas Lines: Copper's resilience and leak-proof properties make it suitable for natural gas and propane lines.

- Industrial Applications: Used in machinery and processing systems that require corrosion-resistant and conductive tubing.

Copper pipes come in different types (Type K, Type L, Type M) that vary in wall thickness and are selected based on specific requirements for pressure resistance and durability. Additionally, they are flexible (annealed) or rigid, making installation easier for complex systems. Copper pipes are available in various diameters and lengths, with options for both straight and coiled formats, allowing adaptability to different construction needs.

Exceptional Conductivity and Durability

Both copper and brass pipes are engineered for outstanding electrical and thermal conductivity, making them ideal for demanding environments. Their superior corrosion resistance ensures longevity, even in challenging atmospheric and water-based settings. The high tensile strength and varied hardness levels further enhance their reliability for structural and utility applications.

Wide Range of Sizes and Customization

These pipes come in inner diameters from 4 mm up to 95 mm and can be supplied in tailored lengths from 1 to 6 meters. Multiple wall thickness options and surface treatments such as polishing or annealing enable seamless integration into your project, whether it's industrial, commercial, decorative, or residential.

Versatile Applications and Easy Processing

Copper and brass pipes are designed for plumbing, HVAC, refrigeration, gas lines, and ornamental use. They are easy to bend and join using welding, soldering, or brazing, streamlining installation and maintenance. Both materials deliver dependable performance in pressure systems, supporting ratings up to 600 psi, depending on pipe size.

FAQ's of COPPER PIPE AND BRASS PIPE:

Q: How do I select between copper and brass pipes for my project?

A: Copper pipes are generally preferred for plumbing and electrical conductivity applications, thanks to their purity and reliability. Brass pipes, with their enhanced machinability and corrosion resistance, are excellent for decorative, HVAC, and certain industrial usages. Consult with your supplier to match material properties with your specific requirements.Q: What is the manufacturing process for copper and brass pipes?

A: These pipes are manufactured via drawing, extrusion, or pressing, depending on the required specification and application. After shaping, surface treatments such as polishing, annealing, or electrolytic finishing are applied to enhance appearance and performance.Q: When will my order be delivered after placing it?

A: Delivery times typically range from 7 to 30 days after order confirmation, depending on the required size, quantity, and any custom specifications. International delivery times may vary based on logistics.Q: Where are these pipes commonly used?

A: Copper and brass pipes are widely utilized in plumbing, HVAC systems, refrigeration units, gas pipelines, and decorative installations due to their adaptability and resilient properties.Q: How are copper and brass pipes joined during installation?

A: These pipes are easy to work with and can be joined using welding, soldering, or brazing techniques. Their formability allows for effective bending and fitting on-site, facilitating hassle-free installation.Q: What are the benefits of using copper or brass pipes in my system?

A: Key benefits include outstanding corrosion resistance, high strength, ease of installation, superior conductivity, and availability in lead-free grades. This ensures longevity, safety, and efficiency across applications.Q: Is there a difference in weight between copper and brass pipes?

A: Yes, copper pipes are slightly denser (8.96 g/cm3) compared to brass pipes (8.44 g/cm3). The actual weight depends on pipe length, diameter, and wall thickness.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Copper Products Category

Copper Anode

Price 445 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Color : Golden

Hardness : Yes

Warranty : Yes

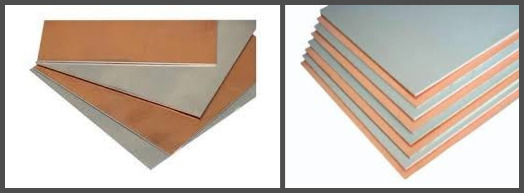

BIMETALLIC SHEET

Price 900 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Color : Sliver Brown

Alloy : No

Chromium Copper Rod

Price 650 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Color : Golden

Hardness : Yes

Warranty : Yes

Alloy : Yes

Copper Flexible Link

Price 750 INR / Piece

Minimum Order Quantity : 10 Pieces

Color : Golden

Hardness : Yes

Warranty : Yes

Alloy : Yes

Send Inquiry

Send Inquiry Send SMS

Send SMS