COPPER SHEET

COPPER SHEET Specification

- Finish

- Smooth

- Size

- Standard & Custom Sizes

- Condition

- New

- Surface Treatment

- Polished

- Cross Dimension

- As per requirement

- Product Type

- Copper Sheet

- Shape

- Rectangular

- Strength

- High conductivity

- Hardness

- Soft, Half Hard, Full Hard

- Alloy

- Electrolytic Tough Pitch Copper (ETP)

- Grade

- C11000 / ASTM B152

- Length

- 1000 mm to 3000 mm

- Width

- 300 mm to 1250 mm

- Thickness

- 0.3 mm to 10 mm

- Color

- Reddish Brown

- Electrical Conductivity

- > 97% IACS

- Lead Time

- 7-10 Days

- Tensile Strength

- Around 210 MPa

- Machinability

- Good

- Supplier Capability

- Cut To Size & Custom Orders

- Density

- 8.96 g/cm³

- Applications

- Electrical, Industrial, Architectural, Arts & Crafts

- Packaging

- Standard Export Packaging

- Melting Point

- 1083°C

- Temperature Range

- -196°C to 350°C

- Corrosion Resistance

- Excellent

COPPER SHEET Trade Information

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Days after Acceptance (DA), Letter of Credit (L/C)

- Supply Ability

- 1000 Per Day

- Delivery Time

- 15 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- WOODEN BOX, HESSIAN CLOTH, PALLETE PACKING ETC.

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- IS, ASTM, EN AND MANY MORE

About COPPER SHEET

Exceptional Electrical and Mechanical Properties

The copper sheet showcases superior electrical conductivity above 97% IACS and a tensile strength of approximately 210 MPa. Electrolytic Tough Pitch (ETP) copper, used in this grade, ensures reliable performance and endurance under different conditions. With a temperature resistance from -196C to 350C and a melting point of 1083C, this sheet is well-adapted for both indoor and outdoor applications.

Customizable Sizes and Finishes

Suppliers offer copper sheets in a range of dimensions: length from 1000 mm to 3000 mm, width from 300 mm to 1250 mm, and thickness between 0.3 mm to 10 mm. Shapes are primarily rectangular, but cross dimensions can be tailored to specific requirements. Customers may also choose from various hardness options-soft, half hard, or full hard-and request polished or smooth surface finishes to best suit their project goals.

Reliable Packaging and Swift Delivery

Copper sheets are shipped in standard export packaging, ensuring safe transit and preservation of quality. With supplier capabilities that include cut-to-size and custom orders, lead times are efficient, typically ranging from 7 to 10 days. Manufacturers, dealers, and exporters across India stand ready to fulfill both small and large volume orders.

FAQ's of COPPER SHEET:

Q: How can I order custom-sized copper sheets according to my project needs?

A: You can submit your specific size requirements for length, width, thickness, and preferred finish directly to the supplier or manufacturer. They offer cut-to-size and custom orders to match individual project specifications.Q: What benefits does Grade C11000 Copper Sheet offer for electrical applications?

A: Grade C11000, with over 97% IACS electrical conductivity and high tensile strength, provides optimal performance in electrical systems, ensuring efficient current flow, minimal energy loss, and reliable long-term durability.Q: When can I expect delivery after placing an order for copper sheets?

A: Lead time for these copper sheets is typically 7-10 days, depending on order volume and customization requirements. Most suppliers prioritize prompt handling and secure packaging for timely delivery.Q: Where are these copper sheets commonly used in architectural projects?

A: Copper sheets are utilized in roofing, facade cladding, decorative trim, and interior design elements due to their smooth finish, excellent corrosion resistance, and attractive reddish-brown color.Q: What is the process for surface treatment and finishing of the copper sheets?

A: The copper sheets undergo careful polishing to achieve a smooth and visually appealing surface. This process enhances corrosion resistance and ensures the material's durability in various environments.Q: How does excellent corrosion resistance benefit industrial copper sheet users?

A: Outstanding corrosion resistance protects the copper sheet from environmental degradation, enabling prolonged service life in industrial equipment, machinery, and exposed installations.Q: Can the copper sheet be easily machined for arts and crafts or industrial fabrication?

A: Yes, the copper sheet possesses good machinability, making it easy to cut, shape, and fabricate. Its availability in soft, half hard, and full hard tempers allows for flexible usage across creative and industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Copper Bar Category

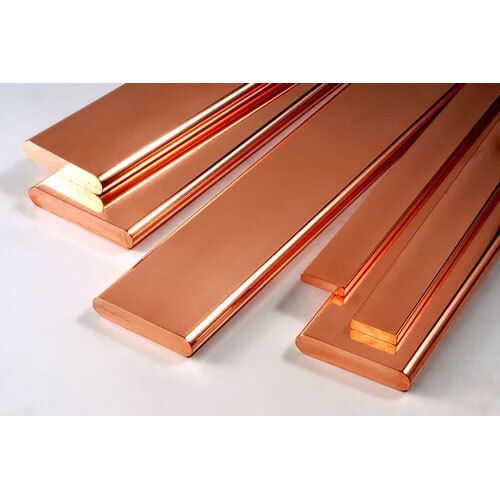

Copper Flat Bars

Price 460 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Warranty : Yes

Grade : Industrial

Color : Golden

Hardness : Yes

Copper Bus Bar

Price 500 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Warranty : Yes

Grade : Industrial

Color : Golden

Hardness : Yes

GI Flat Bar

Price 60 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Warranty : Yes

Grade : Industrial

Color : Silver

Hardness : Yes

Copper Laminated Busbar

Price 1250.0 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Warranty : Yes

Grade : Industrial

Color : Golden

Hardness : Yes

Send Inquiry

Send Inquiry Send SMS

Send SMS