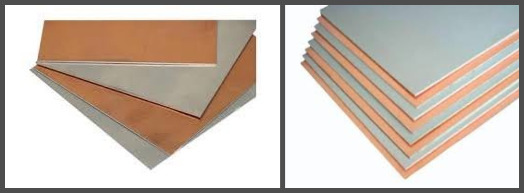

Phosphorous Copper Anode

460 INR/Kilograms

Product Details:

- Hardness Yes

- Grade Industrial

- Click to View more

X

Phosphorous Copper Anode Price And Quantity

- 100 Kilograms

- 460 INR/Kilograms

Phosphorous Copper Anode Product Specifications

- Industrial

- Yes

Phosphorous Copper Anode Trade Information

- Cheque Letter of Credit (L/C) Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID) Days after Acceptance (DA) Letter of Credit at Sight (Sight L/C) Cash Against Delivery (CAD)

- 1000 Kilograms Per Day

- 15 Days

- No

- Contact us for information regarding our sample policy

- WOODEN BOX , HESSIAN CLOTH AND PALLETE PACKING

- Central America North America Asia Australia South America Eastern Europe Western Europe Middle East Africa

- All India

- ISO, ASTM, EN AND MANY MORE

Product Description

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free